ADVENTURES IN ARCHITECTURE: THE SERIES

Il Duomo: Brunelleschi and the Dome of Santa Maria del Fiore

Episode 7: The Machines

by Jim Atkins, FAIA, FKIA

Illustrations by Jim Anderson

Summary: Return with us to the 15th century as we accompany Filippo in his quest to solve the technological challenges of lifting the dome materials high into the air. We will experience his triumphs in designing and constructing equipment that outlasted the great master himself; accomplishments that a young Leonardo da Vinci would later admire and record with his drawings. Join us as we look at the great machines that would change architecture; inventions that would enable and perhaps launch the beginning of that golden age known as the Renaissance.

Introduction Introduction

In our last episode, we explored the innovative components designed by Filippo that played an important part in the construction of the dome of Santa Maria del Fiore. Known primarily for the infamous tension rings that were employed to hold the sides of the dome together like hoops in a wooden barrel, the dome also contains other key components that play a critical role in its success.

The horizontal arches that secure the dome to the vertical ribs, the herringbone brick pattern that directed forces downward instead of inward, and the dual dome system that braced the two shells together to give more strength, are vital elements working together with the rings to support the largest masonry dome in existence. But the dome’s magnificent parts and pieces could not have been assembled had there not been a way to lift the building materials up to their lofty location and move them into place. Yet in the days of Filippo, this technology simply did not exist.

Existing technology

At the time that Filippo was contemplating his design of the dome of Santa Maria del Fiore, the technology for lifting and moving heavy loads was quite limited. Some years earlier, when the drum that supports the dome was under construction, a treadmill-driven device was used. This machine, known as the rota magna, or great wheel, was driven by men walking inside a vertical drum that turned a shaft. This technology had been in existence since antiquity, and it is described by Marcus Vitruvius Pollio in the tenth of his Ten Books on Architecture, written 30-20 BCE.

Then another cable, wound around the drum, is led to a capstan, and … they raise loads gently and without danger … then people using it as a treadmill can complete the task still more quickly.

Filippo was aware that the existing machines could not accomplish the tasks required to construct Il Duomo, and you may recall from our Episode Two that the Opera del Duomo had called for hoisting designs in their initial RFP for the dome in 1418. The genius of Brunelleschi was that he could rise to all occasions. He could provide inventions and designs, and he could oversee their construction to achieve the necessary end for accomplishing his design objectives. We should all be grateful that we don’t have to compete with him for projects today.

No documentation

Brunelleschi left no drawings or written descriptions of his machines, but fortunately they survived him, although not through continuous use. Their innovative features were admired by many engineers of the time, and they were studied and sketched by those who followed him. One such engineer was a young apprentice named Leonardo da Vinci. He was fascinated by Filippo’s inventions and went on to design machines of his own. His sketches of Filippo’s work were of such detail that some have mistakenly attributed the great master’s work to Leonardo himself.

In recent years, craftsmen have built reproductions of Filippo’s work. These models are works of art unto themselves and can be viewed at the Opera di Santa Maria del Fiore Museum in Florence.

Filippo’s three-speed hoist

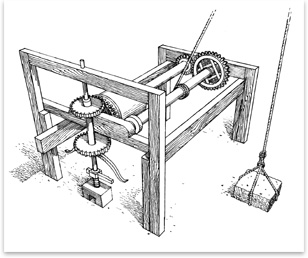

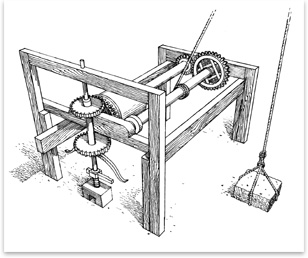

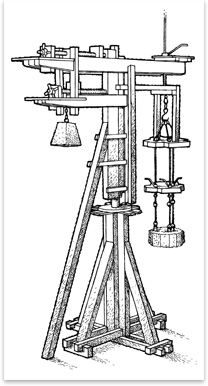

As we observed in Episode 3, Filippo’s response to the competition for lifting devices in 1418 resulted in his three-speed hoist, completed in 1420. It was configured as a heavy, rectangular frame with four sturdy legs anchored to the ground. Two horizontal geared wheels operated at each end of a vertical shaft, capable of engaging a vertical geared wheel independently, thus enabling the reversing feature.

The vertical geared wheel drove a cylindrical shaft of two different diameters. A third cylindrical shaft of yet a third diameter was driven by the vertical shaft through the use of a pinion and geared wheel system. The lifting ropes were wound around each cylinder depending on the load to be hoisted. A heavier load was raised more slowly on the smallest cylinder which had the greatest force. Lighter loads were raised on the larger diameter cylinders which resulted in faster hoisting speeds but with less force. The vertical geared wheel drove a cylindrical shaft of two different diameters. A third cylindrical shaft of yet a third diameter was driven by the vertical shaft through the use of a pinion and geared wheel system. The lifting ropes were wound around each cylinder depending on the load to be hoisted. A heavier load was raised more slowly on the smallest cylinder which had the greatest force. Lighter loads were raised on the larger diameter cylinders which resulted in faster hoisting speeds but with less force.

The vertical shaft connecting the horizontal geared wheels was driven by a pair of oxen. A worm screw raised or lowered the vertical shaft as needed to engage the upper or lower wheels and hoist upward or downward. Two oxen provided the power, and the efficiency of not having to unhitch the oxen and reverse them to lower the rope resulted in much faster payload trips to the top and back down.

A study of the gears and shafts of this innovative lifting device reveals its similarity to a giant clockwork. Filippo’s earlier stint as a clockmaker ultimately paid off through his creation of the monumental lifting machines.

The castello The castello

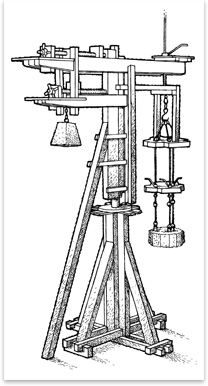

Once the materials were hoisted to a workable elevation, they had to be moved horizontally for placement. This was achieved by another machine also designed and built by Brunelleschi called the castello. Standing 65 feet tall with the ability to rotate 360 degrees, its proportions and movements interestingly resemble the tower cranes in use today.

When the vertical hoisting was accomplished, the load and the counterweight were moved in opposing directions by simultaneously turning two horizontal screws to maintain balance of the load on the tall framework. Since movement of the load at this point was essentially horizontal, and it only had to be lifted clear of its resting place, this was accomplished with a vertical screw instead of a rope hoist.

The operation of the machine required four crews of workers. One crew hoisted the load with the vertical screw, two other crews operated the screws to move the payload and the counterweight in opposing directions to maintain balance while moving the load horizontally, and a fourth crew rotated the crane to move the load in the proper direction.

Many of the dome components weighed in excess of a ton, and placement of these materials without Brunelleschi’s great machines would have taken many times longer, if the task were even possible.

The lantern cranes

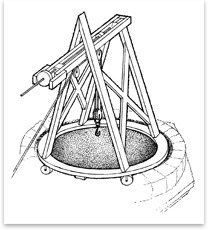

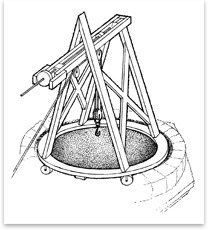

Although Filippo did not live to see the dome lantern constructed, the two cranes that were used to move the stones in place were essentially of his design. The first rested at the center of the oculus and allowed both vertical and radial movement of the loads. This machine was used to construct the lower portion of the lantern.

The second crane rested around the lantern spire, after the base was completed, and it was used to construct the upper part of the lantern and install the copper ball and cross at the top. It had a revolving boom that was horizontally adjustable as well as a pulley hoist inside the platform for vertical lifting. The second crane rested around the lantern spire, after the base was completed, and it was used to construct the upper part of the lantern and install the copper ball and cross at the top. It had a revolving boom that was horizontally adjustable as well as a pulley hoist inside the platform for vertical lifting.

Objects of Florentine pride

Never before had materials of such weight been raised to such heights and placed with such precision. The ingenuity and capability of these magnificent machines rivaled the accomplishments of the dome itself.

It has been recorded that the oxen raised 50 loads per day ranging from hundreds of pounds to multiple tons. Assuming an eight-hour work day, each round-trip load would be completed in less than 10 minutes on average, including attachment and detachment of materials.

Filippo was awarded a prize for his inventions and compensation for his expenses on the three-speed hoist. In all it came to almost 200 florins. It is interesting that while his work as a contractor producing the lifting machines resulted in timely payment, his compensation as an architect was slow and not always made. Hmmm, maybe this is where it all began.

The three-speed hoist was quite visible to the townspeople, who celebrated it as an object of national pride. The machines are reported to have operated for over 10 years, with only minor repairs required and no complaints. It’s a good thing, because this was before product liability insurance was available.

The end of the machines The end of the machines

Interestingly, although the machines were celebrated and graphically recorded many times, they ultimately disappeared from use. The cause is much debated, but it is speculated that the Renaissance brought with it the reappearance of mechanical concepts put forth by Vitruvius and other ancient teachings, and technological advancement actually retreated for a time. In any event, Filippo’s great machines fell into disuse and were ultimately disregarded.

Great inventions such as these machines would be expected to reappear in subsequent construction work, but they did not. As Prager and Scaglia put forth in their book, Brunelleschi: Studies of His Technology and Inventions:

“It is conceivable that Filippo was too far ahead of his time and therefore unable to influence his time with regard to machines … They are part of the effort of a Gothic master, operating in his Gothic world. It may be for this reason that they were promptly forgotten. They were ingenious, but they belonged to a world then about to disappear, not to the world of his real successors or of his own major enterprises as architect.”

After Filippo’s machines fell into ruin and were forgotten, there is no record of anyone developing or using hoisting systems as advanced until the onset of the Industrial Revolution in the late 18th century. This profound and unfortunate event in history is a lesson to be coveted and preserved. If we are to advance and improve ourselves, we must never disregard or disrespect even the most humble innovations and accomplishments of our peers or predecessors. |

The vertical geared wheel drove a cylindrical shaft of two different diameters. A third cylindrical shaft of yet a third diameter was driven by the vertical shaft through the use of a pinion and geared wheel system. The lifting ropes were wound around each cylinder depending on the load to be hoisted. A heavier load was raised more slowly on the smallest cylinder which had the greatest force. Lighter loads were raised on the larger diameter cylinders which resulted in faster hoisting speeds but with less force.

The vertical geared wheel drove a cylindrical shaft of two different diameters. A third cylindrical shaft of yet a third diameter was driven by the vertical shaft through the use of a pinion and geared wheel system. The lifting ropes were wound around each cylinder depending on the load to be hoisted. A heavier load was raised more slowly on the smallest cylinder which had the greatest force. Lighter loads were raised on the larger diameter cylinders which resulted in faster hoisting speeds but with less force. The castello

The castello The second crane rested around the lantern spire, after the base was completed, and it was used to construct the upper part of the lantern and install the copper ball and cross at the top. It had a revolving boom that was horizontally adjustable as well as a pulley hoist inside the platform for vertical lifting.

The second crane rested around the lantern spire, after the base was completed, and it was used to construct the upper part of the lantern and install the copper ball and cross at the top. It had a revolving boom that was horizontally adjustable as well as a pulley hoist inside the platform for vertical lifting. The end of the machines

The end of the machines