| Fallingwater The Story of a Country House The Failure of Fallingwater Summary: In this, the fifth of the series, Jim Atkins takes us on a forensic exploration of the nation’s most famous house, including a few lessons on the structural properties of reinforced concrete, both initially and over time under the cyclical duress of sagging, cracking, and weathering—properties much better understood today than in 1935. “The calculated stresses in the structure do not fall within the limits of those prescribed by accepted engineering practice … therefore the structure does not have a satisfactory factor of safety …”

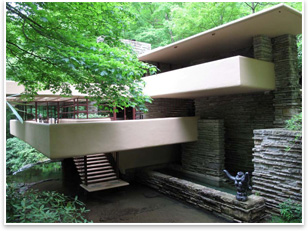

View of the terraces over Bear Run. Photo by James B. Atkins, courtesy of the Western Pennsylvania Conservancy. As described last month in Part 4, construction finally began on Fallingwater after a much delayed start. Most of 1936 had passed without significant progress, beginning with Edgar Kaufmann’s doubts about the structure, followed by late changes by Wright in the supporting concrete bolsters, and further complicated by the difficulty in finding a competent contractor. Finally, when work began in earnest the project was plagued with yet another challenge—one with potentially fatal consequences: a progressing failure in the building’s structure. Join us as we experience the ultimate challenge in constructing the country house known as Fallingwater. A complex design As the use of concrete has become more widespread over the years, more has been learned, and today there are many tools to employ, such as higher strength concrete, high-tensile reinforcing steel, and more advanced curing techniques to apply after the concrete has been placed in the formwork. Reshoring, or temporary bracing placed under a suspended concrete structure for a period of time after the formwork has been removed, usually requires its own engineering design. Reshoring prevents the concrete from moving, or in this case deflecting, until it reaches its ultimate design strength, typically calculated at 28 days after placement. Concurrent with the construction of Fallingwater, the mushroom-shaped columns at the Johnson Wax Company building designed by Wright and the same structural engineer were being challenged by local authorities. In that case, they load tested a column to failure to verify its capacity. Kaufmann’s country house was not a publicly accessed building, and it was not in a city that required a building permit. There was no third-party authority to oversee and agree with this unique structural design. It is easy to blame Wright for his failed cantilevers, but like the architects of today, he relied on technology available at the time to deliver his product. The awe of his work is that he actually produced such an innovative design with those materials in that time and place. Frank Lloyd Wright and the Cantilever The definition of failure Edgar J. Kaufmann jr., in his book, Fallingwater, A Frank Lloyd Wright Country House, vigorously defends what he calls “The Faults of Fallingwater.” He begins with the rationale: “Mistakes have plagued Fallingwater, yet the extraordinary beauty of the house and the delight it brought to the life of its inhabitants form the context in which its construction should be evaluated.” If only architects today could be looked upon with such sympathy and understanding; if today our honest mistakes could be understood when compared to the benefits we achieve with the performance of our project. If only our clients would speak as Edgar jr. spoke: “No apologies are necessary for what he [Wright] achieved at Fallingwater.” We are all aware that in this time such failures are not tolerated whatsoever. If Wright delivered such a product to Kaufmann today, he would likely be sued for loss recovery against his professional liability insurance policy, even if he and Kaufmann remained good friends. Wright did not carry professional liability insurance because it did not exist at the time. Ironically, until professional liability insurance was invented in the 1950s, no one appeared to be interested in getting into the architect’s pocket. Considering Wright’s history of building design failures, if his work were produced in today’s market, he may not experience the same level of historical prominence. The structural failure that plagued Fallingwater is filled with complexities that may never be completely revealed or resolved. But like the Torre Pendente di Pisa, the ending is a happy one because in 2002 the progressing failure was ultimately arrested with modern structural technology. And like the famous Italian bell tower, the existing deflections in the floors of this famous house now only add to its rich history and intriguing notoriety. Lightning and inevitable thunder New steel was ordered, and it was delivered on the site on August 15. The placement of the concrete for the cantilever was scheduled for August 19. Walter Hall, Kaufmann’s contractor, subsequently added steel to the structure, but he did not add the full amount called for by Metzger-Richardson. The final, in-place design was more than Wright called for but less than Kaufmann’s engineers required. It is convenient to conclude that this is why the cantilevers continued to deflect and were ultimately determined to be structurally inadequate. Wright knew nothing of the added steel until he received a letter from Bob Mosher on August 25. When Wright learned of the additional engineer and their recommendation for added steel, he was outraged. His letter to Kaufmann followed.

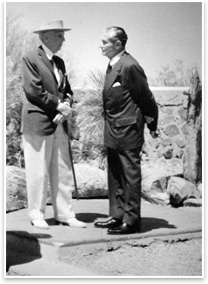

Wright and Kaufmann remained close despite the occasional lightning and thunder. Photo courtesy of the Western Pennsylvania Conservancy. Wright chided Kaufmann for his provincial attitude and overriding the architect’s decisions. He told him it was not too late to get another architect, and he called his apprentice Mosher back to Taliesin. His closing was equally acrimonious.

Kaufmann came back at him with a letter that closely mimicked Wright’s.

He concluded with a postscript that suggested they stop writing letters and for Wright to come to Pittsburgh to clear the matter up. He expressed regret that Wright was calling Mosher back to Taliesin, and he said that, because of their past good relationship, he would consider that Wright’s letter had never been written. He initialed the postscript as if it were a separate letter. Wright, never the fool, began his reconciliation in a letter on August 31. However, the letter was more explanatory than apologetic, and Wright continued to stress that, “the details must be mine.”

Multiple causes and effects

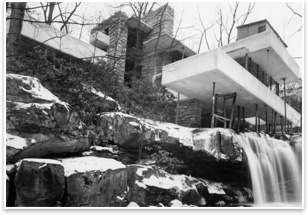

This photo shows the apparent lack of planning in placing the temporary shoring for the cantilevered terrace. Photo courtesy of the Western Pennsylvania Conservancy. There is no record of a reshoring design, and the supporting braces placed after the forms were removed appear to have been randomly placed, more of convenience than design. The random reshoring is visible in an image recording the original construction. It is also not known how long the reshoring remained after the concrete was in place. Removing the supports before the concrete reached its full design strength could have contributed to the distress experienced at Fallingwater. Cracks initially began to manifest in the second story parapets. When Hall placed the concrete roof over the guest room terrace on October 29, cracks immediately appeared. Wright was concerned about the cracks, and he had Hall take measurements and send them to Glickman. Hall discounted the cracks as caused by an absence of expansion joints. He wrote, “These cracks mean nothing in my opinion …” On the spot in Pittsburgh Meanwhile, Kaufmann hired Metzger-Richardson to do a full structural analysis. They reported back that the cantilevers had been overstressed beyond design, and they recommended permanent supports be placed under them. By January Metzger-Richardson had declared the terrace at Kaufmann’s bedroom in danger of catastrophic failure, and workers installed a supporting wall under it. Metzger-Richardson performed load testing on the cantilever using bags of sand and cement and cast iron pipes for weight. Many overhangs were determined to be safe, but the tests caused cracks in Liliane’s terrace. Meanwhile, back at Taliesin, Wright admitted to Glickman: “We are on the spot in Pittsburgh.” It took until the end of January for Wright to learn of the load tests. When he did, he telegraphed Kaufman with more lightning and thunder, and Kaufmann returned the same. Volatility was not in short supply. As their tempers ultimately cooled, Wright sent a printed form for Kaufmann to sign. It stated that Kaufmann agreed to make sure that the architect’s instructions would be faithfully executed, with no exterior advice or criticism that would interfere with the architect’s authority until the building was completed. The form was never signed. In spite of progressing deflection and cracking, Wright continued to assure Kaufmann that the design was adequate. Kaufmann was apparently persuaded, and he directed Hall to remove the shoring that had been placed under the west terrace by Carl Thumm at the beginning of the year. The cantilevers would now rest unsupported, proudly extending over the streambed below as Wright originally conceived. These conditions would remain until forensic evaluations revealed fatal developing conditions in the late 1990s. Meanwhile, Edgar Kaufmann Sr. would fret and worry about the cantilevers the remainder of his life, having them constantly monitored and measured. Repair and redemption Silman determined that the cantilevers were in danger of imminent catastrophic failure. Heavy, unattractive steel trusses were installed in 1997 beneath the cantilevers to prevent the house from falling into the creek until remediation could be completed. The visual elegance of Fallingwater was now completely compromised.

The floor of the Great Room removed for the repair. Photo courtesy of the Western Pennsylvania Conservancy. Stretching things a bit

Post-tensioning tendons protruding from the Great Room terrace. Photo courtesy of the Western Pennsylvania Conservancy. One end of each tendon bundle was anchored in a concrete block attached to the beam. The other “live” end of the cables passed through another anchor block in the terrace wall at the unsupported end of the cantilevered beam. Each end of the tendon cables was lower at each end than in the middle, where a higher block was positioned, configuring the cables in an arch. The cables were encased in concrete. Post-tensioned Concrete Hydraulic jacks were attached to the terrace wall end on the protruding cables. Over a two-day period in the spring of 2002 the cables were stretched with the jacks until the end of the cantilever rose back up three quarters of an inch from its deflected position. The cables were stretched until they exerted a force of 195 tons on each side of the beam. The cable “live” ends were anchored, the loose cable ends were removed, and the connector pockets were grouted and finished to appear like the original surface. The progressing and ultimate failure of Fallingwater had finally been arrested and resolved. Meanwhile, the long-term creep in the concrete had left the cantilevers in a permanent deflected condition that could not be remedied by the post-tensioning. Moreover, it was not the intention of the engineers to completely correct the sagging, as it is truly an integral part of the creation of the house. Wright created the drooping cantilevers as much as he created the house itself. Apparently imperfection, in some cases, can become an integral part of perfection. The failure of the cantilevers of Fallingwater fortunately did not bring down the house, and the iconic design is no less evident or truthful because of the flaw. Fallingwater gave Wright new life as an architect in his later years, and it put Kaufmann out in front of his stuffy elitists Pittsburgh contemporaries. The exclusivity of the Duquesne Club pales in comparison to Kaufmann’s preeminent position as Lord of Fallingwater. It gave the Kaufmanns a wonderful place to be together as a family, and it gave the American public, and the world, an iconic masterpiece to be freely enjoyed and that will likely never be surpassed. It is a solemn and profound example of how perfection, in its purest form, can be made up of the perfect and the imperfect. Next month Join us next month for the final part of this series as this author and his wife visit Fallingwater in late May 2009. The weather is ideal, and one can relate to Kaufmann as he came to his country house in the spring to get away from the hectic atmosphere of the store in busy Pittsburgh. We were treated most graciously by the members of the Western Pennsylvania Conservancy, particularly Clinton Piper, a true professional and fitting host. Join us next month on a trip that any architect should seriously consider if he or she has a meaningful interest in American architecture. Meanwhile, good luck out there. |

||

Copyright 2009 The American Institute of Architects. All rights reserved. Home Page |

||

news headlines

practice

business

design

recent related

› Fallingwater Part 1: The Story of a Country House—The Kaufmanns

› Fallingwater Part 2: The Story of a Country House—Bear Run, Kaufmann, and Wright

› Fallingwater Part 3: The Story of a Country House—The Design

› Fallingwater Part 4: The Story of a Country House—Construction

Jim Atkins is president of Atkins Consulting Solutions, a firm that provides litigation support services and representation for owners and lenders.

Further Reading

Fallingwater: A Frank Lloyd Wright Country House, Edgar Kaufmann, jr., Abbeville Press Publishers, New York, 1986

Fallingwater Rising: Frank Lloyd Wright, E.J. Kaufmann, and America’s Most Extraordinary House, Franklin Toker, Alfred A. Knopf, New York, 2005

Frank Lloyd Wright’s Fallingwater, Carla Lind, Archetype Press, Inc., San Francisco, 1996

Frank Lloyd Wright’s Fallingwater: The House and Its History, Donald Hoffman, Dover Publications, Inc., New York, 1978, 1993

Merchant Prince and Master Builder: Edgar J. Kaufmann and Frank Lloyd Wright, Richard L. Cleary, Carnegie Museum of Art, 1999

The Fallingwater Cookbook: Elsie Henderson’s Recipes and Memories, Suzanne Martinson, Jane Citron, Robert Sendall, University of Pittsburgh Press, 2008

Years With Frank Lloyd Wright: Apprentice to Genius, Edgar Tafel, Dover Publications, Inc., New York, 1979