| Eco-office Promotes Regenerative Design Sustainability moves toward not just using less, but also giving back How do you . . . as an architecture firm, live the green life?

“Environmental Dynamics wants to partner with people in the community to start developing buildings that are regenerative; i.e., buildings that give back to the community and allow some reversal of this global warming process,” says McGee. “That’s how EDI is continuing to adapt, by trying to interpret and lead the way in this green building movement. We’re trying not to get too far ahead of [the clients] so that we can actually make a living, but we’re always trying to figure out a way to do it better.” Instead of just creating zero emissions, it’s giving something back Partner Mike Ryan defines regenerative design as a building that gives back instead of taking. An example of a regenerative building is one that uses more recycled than raw materials in its construction so that it actually consumes the by-products from other industries. “If a building can use those up, it’s giving back to the community as a whole,” explains Ryan. “Then, in terms of lifecycle, the building is equipped with power generation so that not only does it run on its own power, but it generates more than enough to sell back. Instead of just creating zero emissions, it’s giving something back.”

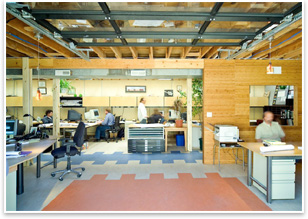

One of the most effective strategies for minimizing the environmental impact of material use is to reuse existing buildings. In addition to reusing 50 percent of the existing shell and structural elements, much of the purchased construction material was reused, refurbished, or salvaged. In the process of rebuilding, EDI was able to divert over 85 percent of the construction waste from the landfill to recycling and salvage centers. EDI was able to divert over 85 percent of the construction waste from the landfill to recycling and salvage centers “We either adaptively reused the materials or donated them to organizations like Habitat for Humanity Re-store,” notes McGee. “When we reduced the parking area, we rented a truck, loaded up the asphalt, and took it back to LaFarge so they could put it back into asphalt emulsion. If all else failed, then we took materials to the dump.” About their reuse philosophy, Ryan adds, “It definitely took a little more work than just hauling the materials out to the dump, but we felt that was worth it.”

EDI used a 90-percent recycled glass, lime, and stucco system For its skin, EDI used a 90-percent recycled glass, lime, and stucco system developed by American Clay. “The fantastic part about this recycled glass, lime, stucco system is that you can get the recycled glass in any city in the U.S.A.,” explains McGee. “It is a leftover byproduct, so there’s almost no energy in the conversion. All you’re doing is putting it through a sieve to get the sizes you need.” McGee also notes that whereas cement will draw water into the wall, the lime-based application pulls water out, inhibiting mold growth. And, as an added cost-saving benefit, application is so easy that the EDI team even applied it themselves. Finally, EDI created a 350-square-foot green roof, reduced the amount of onsite parking by 10 percent, introduced pervious paving and a wheat gluten-based sidewalk, and buried cisterns to capture and store rainwater. Ryan notes that included in their water efficiency efforts is the commitment to use potable and graywater as many times as possible before releasing it into the aquifer. |

||

Copyright 2007 The American Institute of Architects. All rights reserved. Home Page |

||

news headlines

practice

business

design

Photos © Patrick Coulie.

For the glass, lime, and stucco system, EDI had to write a performance-based spec to the International Building Code. To assist other architects who may be interested in this system, EDI has made available a free, downloadable white paper on the material and process through the USGBC.