| Architecture Problem Solving Pairs Two Post-Katrina Needs in One A new laundromat becomes a small-town community center How do you . . . hold a design workshop to identify and meet a community’s most basic of needs? Summary: On this the fourth anniversary of Hurricane Katrina it is fitting to look back on how architectural problem solving can turn even a seemingly small project into a huge improvement in a community’s quality of life. In this instance, architecture design students at Parsons the New School for Design held a workshop in 2006 in DeLisle, Miss., that resulted in the design and construction of InfoWash, a 2,000-square-foot facility that provided both a 24-hour laundromat and a community center. (New York-based SHoP Architects served as architect of record.) The concept was born due to the number of homes without washing machines, a result of Katrina’s devastation.

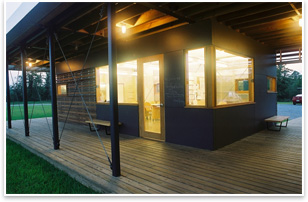

Architecture design students at Parsons the New School for Design devised InfoWash, a 2,000-square-foot facility in DeLisle Miss., that gives residents rebuilding assistance and a 24-hour laundromat. A breezeway separates the laundry and information wings. Photo courtesy The Design Workshop, Parsons the New School for Design. DeLisle is a small town, located 70 miles east of New Orleans, with a post-Katrina population of approximately 1,000. The Parsons design workshop comprised 13 design students. The project was initiated by local Mississippi resident Martha Murphy, the client. Following the devastation of the region, including the destruction of her own residence, Murphy invited SHoP Architects to DeLisle to work on a relief community center. A member of SHoP, Federico Negro, was a recent graduate of Parsons’ architecture program. He and SHoP Architects connected the Parson workshop with the Mississippi rebuilding efforts. Serving as architect of record, SHoP Architects helped move the Parsons InfoWash project forward, providing insight, checking and stamping the drawings, and helping with permitting. From the outset, the SHoP community center design was intended to provide support for local businesses. During design development, Murphy also recognized a need for a community information center where residents could get logistical, financial, and support services. The Parson design workshop participants also discovered that the community had few working private laundry machines and no intact laundromats. Combining both programmatic needs, the design workshop developed InfoWash, both an information center and a central laundry facility.

InfoWash is a steel and wood framed structure, braced by cables. Photo courtesy The Design Workshop, Parsons the New School for Design. InfoWash is born David J. Lewis, principal, LTL Architects and associate professor at Parsons the New School for Design, says the design workshop’s 13 students, rethought the initial client brief and presented back three very different projects. The process yielded a clear need for an information exchange point in the community. “People who either lost their housing or needed to find resources could have a point for the culmination of private and public information about what was available for rebuilding in the area,” Lewis explains.

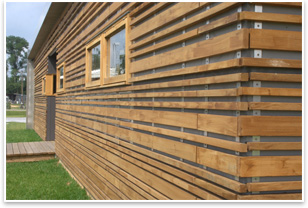

The façade is wood slat siding attached to aluminum straps. Photo courtesy The Design Workshop, Parsons the New School for Design. DeLisle’s town hall had been destroyed and there was no building department, Lewis points out. “What the group in combination with the client realized was that to get people to come to the facility it had to have something ordinary, everyday, and matter-of-fact,” Lewis says. “What was really missing was the fact that everyone had lost their washing machines. The few people who had working washing machines were on high enough ground and doing the wash for everyone in the neighborhood, 16 hours per day.” Lewis says the students worked on a design that would incorporate into one structure laundry machines and an information area. The two distinct services, however, would be in separate spaces but share a waiting area.

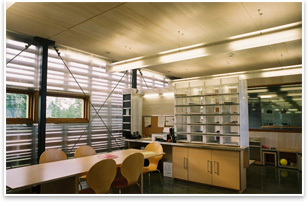

Inside the information center, small spaces serve multiple functions. Desks and walls pivot and close, turning the office space into a secure private meeting area. Photo courtesy The Design Workshop, Parsons the New School for Design. Do laundry; get information “You do your wash and sit in the other area to wait, and in doing so you come across people who provide information,” Lewis says. “So it will break down the sense of asking for help you want to avoid, but still offer the ability to get information that is critical, such as a FEMA sign-up deadline. That was the conjunction of the two programs. They are intentionally in two different spaces to mitigate the sense of both guilt and reduce the ambiguity of having to go for help.”

The façade ties translucent cladding and the steel walls. Photo courtesy The Design Workshop, Parsons the New School for Design. Design materials InfoWash is a steel and wood framed structure, braced by cables, with translucent cladding, windows, concrete floors, and a plywood ceiling. The façade is wood slat siding attached to aluminum straps, which ties the translucent cladding and steel walls. “The selection of materials was a combination of things that were relatively inexpensive but durable, and would produce something that would have an enduring quality,” Lewis explains. “The steel chosen for the project is to deal with sizable hurricane loads and to brace the project in as sufficient a manner as possible. By taking the load off the walls, they can become much more luminous and glowing and not take on the typical responsibility of platform or balloon framing. That was essentially the structural argument—that the team can frame something faster out of steel, given the difficulty of actually getting wood in the area because all the lumber yards were wiped out.” Western Red Cedar was chosen for both its availability and its resistance to termites.

The steel frame allows for translucent cladding that becomes luminous. Photo courtesy The Design Workshop, Parsons the New School for Design. Inside the information center, small spaces serve multiple functions. Desks and walls pivot and close, turning the office space into a secure private meeting area. In the waiting area, mobile chairs and storage boxes for children’s toys slide out from a bench. The laundry area has a counter that integrates a folding table, seat, and ironing station. Lewis says he doesn’t think the InfoWash facility will last beyond the post-Katrina rebuilding efforts, but for now the program is playing a vital and particular role to the conditions in DeLisle. |

||

Copyright 2009 The American Institute of Architects. All rights reserved. Home Page |

||

news headlines

practice

business

design

recent related

› Design Student Studios Offer Real-World Experience for Students