New

and Cool: Variable Refrigerant Flow Systems New

and Cool: Variable Refrigerant Flow Systems

Superior control and efficiency are

bringing VRF systems to America

by Sara Fernández Cendón

Summary: Variable

refrigerant flow (VRF) systems have been around for almost three

decades, but they’re new to the U.S. HVAC market. As American

engineers become familiar with the technology, and especially as

they learn of its energy efficiency advantages, more in the industry

might be willing to give the systems a try.

1: CITY MULTI VRFZ systems are installed on the roof of the Burlingham

Hall residence hall at Pacific University in Pacific Grove, Ore. Image

courtesy of Mitsubishi.

2: Daikin compressing units installed on the roof

of a building. Each of these can be connected to multiple evaporators inside

the building. Image courtesy of Daikin.

3: A central monitor that controls

the entire VRF system. Image courtesy of Daikin.

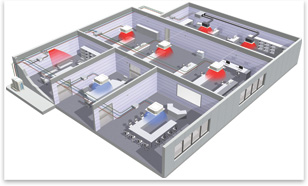

4: A heat recovery system

diagram.

Cooling the old-school way

If you’ve been shopping for HVAC systems lately, you might

have encountered a new contender among the usual choices. Introduced

in the U.S. about five years ago, VRF systems were invented in Japan

more than 20 years ago. They’re widely used not only in Asia,

but also in Europe and South America.

VRF systems manufacturers highlight qualities such as energy efficiency,

design flexibility for architects and engineers, quiet operation,

and the ability the system grants individual users to control temperature

in their own areas. Another appealing feature offered by most manufacturers

is a centralized monitoring application that gives users control

over the entire system from a single location or via the Web. The

technology that makes it all possible is sophisticated, but VRF systems

(also known as VRV, or variable refrigerant volume systems) are not

very complicated.

A quick review of air-conditioning principles might be useful in

describing VRF technology—the most basic principle, of course,

being that air conditioning removes heat from the space to be cooled

by pushing refrigerant through a cycle. The cycle comprises four

elements common to all HVAC systems, which is based on the fluid

dynamics that when a refrigerant expands, it becomes cooler; when

it is compressed, it becomes warmer; and changing phases from fluid

to gas or back again adds to the cooling/warming effect. So the system

is composed of a compressor, a condensing unit, a metering device

(or expansion valve), and an evaporator or heat sink.

In a direct expansion (DX) system, the simplest among air conditioning

systems, the “hot” part of the cycle starts at the compressor,

which compresses refrigerant vapor and turns it into a high-temperature

gas. The refrigerant then goes through a condensing unit, a series

of coils in which the gas loses heat and becomes liquid. The “cold” part

of the cycle begins as the liquid refrigerant passes through the

metering device, which causes a drop in pressure. The refrigerant

then goes through the evaporator (another series of coils), and in

the process of evaporating it absorbs heat from the surrounding area,

producing a cooling effect that is dissipated through fans. After

completing the cycle, the refrigerant goes back to the compressor

in its initial low-pressure, gaseous state.

Slight variations in the refrigerant cycle have led to different

applications designed for different uses. Window units, for example,

pack all the elements of the cycle into one small device—the

hot side being on the outside, the cool part facing the space to

be cooled. Split-system units split the hot side of the cycle (placed

outside the building) from the cold side (inside). In these types

of systems, cool air is often transferred from the evaporator to

many different rooms by an air-handling unit, which distributes the

conditioned air through a series of ducts.

Industry standards set limits on the length of piping running between

the condenser and the evaporator in DX systems. When the needs of

a particular project exceed such limits, chilled water systems are

often used as an alternative. In chilled water systems water is cooled

by a regular refrigeration system and then circulated through ducts

to air handlers throughout the building. Because there is no limit

to the permitted length of water pipes, these systems are often used

to cool large buildings or entire campuses. Chilling is often cycled

at night to take advantage of off-peak energy rates.

The variable beauty of VRF technology The variable beauty of VRF technology

Configurations vary among the types of air-conditioning systems available,

but one key ratio remains the same: always one condensing unit

to one evaporator. For DX systems, this means that once a condensing

unit is connected to an evaporator inside the building, providing

cool air to several spaces requires either ductwork or additional

condensing units and evaporators.

Not so with VRF systems, in which one condensing unit can be connected

to multiple evaporators, each individually controllable by its user.

Similar to the more conventional ductless multi-split systems, which

can also connect one outdoor section to several evaporators, VRF

systems are different in one important respect—although multi-split

systems, like DX systems, turn on and off depending on whether the

room to be cooled is too warm or not warm enough, VRF systems constantly

modulate the amount of refrigerant being sent to each evaporator.

By operating at varying speeds, VRF units work only at the needed

rate, which is how they consume less energy than on/off systems,

even if they run more frequently.

Although systems vary among manufacturers, VRF technology is usually

available as heat pump or heat recovery units. Heat pumps provide

either heating or cooling. Heat recovery systems allow for simultaneous

heating and cooling—which means, for example, that one condensing

unit might be connected to six indoor units, three of which could

be used to cool some areas, and three of which could be used to heat

other areas, all at the same time.

The modular nature of VRF offers a dizzying array of options. And,

to help engineers interested in exploring the use of this technology,

the American Society of Heating,

Refrigerating and Air-Conditioning Engineers (ASHRAE) has assembled a group

to study VRF. ASHRAE included a description of the VRF system in

its 2008 handbook on HVC systems and equipment and is now working

on a separate chapter on VRF to be published in 2012.

Several manufacturers of VRF systems are part of the ASHRAE committee

working on documentation for the technology, but only a handful are

already marketing their systems in the U.S., with Mitsubishi

Electric HVAC Advanced Products Division in Suwanee,

Ga., and Daikin Industries (based in Osaka,

Japan, with U.S. headquarters in Dallas) currently being the major

players.

Both Mitsubishi and Daikin are taking steps to educate U.S. engineers,

architects, and contractors on the technology. According to Meredith

Emmerich, director of application support with Mitsubishi, about

10,000 people went through the company’s training on ductless

and VRF systems last year alone. The company offers support and training

through 1,100 locations across the U.S.

Daikin’s Dallas location, too, includes a training facility

where VRF equipment is installed and exposed, so engineers, architects,

and contractors may come in and see the outdoor and indoor units,

the piping, the installation, and controls on all the models. Daikin’s Dallas location, too, includes a training facility

where VRF equipment is installed and exposed, so engineers, architects,

and contractors may come in and see the outdoor and indoor units,

the piping, the installation, and controls on all the models.

Breaking it down

VRF systems offer an energy-efficient solution that

provides considerable flexibility. But, as with any other HVAC system,

their cost-effectiveness and usefulness needs to be evaluated on

a building-by-building basis. VRF systems are a good option for buildings

with varying loads and different zones: structures such as hotels,

schools, and office buildings where individual users want to have

control over the temperature in their areas. VRF systems tend to

have greater piping length allowances than DX systems and use copper

piping with small diameters, which makes them suitable for buildings

with low-ceiling spaces or for adaptive reuse and other projects

aimed at preserving historic value with minimal destruction during

installation.

Less likely candidates to benefit from VRF technology are large

open volumes, such as gyms, theaters, or sanctuaries. These building

types often fail to maximize the potential of the system, which is

ideal for areas with different zones.

Lee Shadbolt, AIA, principal with Commonwealth

Architects, based in Richmond, Va., says his firm is considering a VRF system

for the renovation of Hotel John Marshall, a historic landmark built

in the 1920s. Energy efficiency was one of the main factors considered,

but there were other reasons to look at VRF.

“First, it’s a great application for multi-familiy residential

use,” he says. “Second, it was extremely efficient and

gave us a lot of points toward LEED certification. And third, it

allowed us to work with the high-rise nature of the building.”

Shadbolt says other options (such as split systems or a central

chiller boiler plant) have been considered for the project. But VRF,

which is about 20 percent more expensive than other alternatives

considered, is also significantly more efficient, according to his

team’s assessment.

Regarding cost, Jami Billman, sales engineer with Daikin, says that

VRF systems can be designed both in expensive and more affordable

ways. For example, a system with one evaporator in every single room

may be more costly initially, but the installation might require

less ductwork. Or, in a different arrangement, several spaces might

share a nearby evaporator. The smaller footprint of VRF equipment

can also reduce costs. According to Billman, in most cases the system

eliminates the need to have mechanical rooms, so useable space is

given back to the client. Regarding cost, Jami Billman, sales engineer with Daikin, says that

VRF systems can be designed both in expensive and more affordable

ways. For example, a system with one evaporator in every single room

may be more costly initially, but the installation might require

less ductwork. Or, in a different arrangement, several spaces might

share a nearby evaporator. The smaller footprint of VRF equipment

can also reduce costs. According to Billman, in most cases the system

eliminates the need to have mechanical rooms, so useable space is

given back to the client.

Joe Bush, application specialist for City

Multi, Mitsubishi’s line of VRF systems, explains that Mitsubishi

is the only manufacturer to use two refrigerant lines, instead of

three, for heat recovery systems. He says this patented technology

translates into considerable installation cost savings as well.

Ramez Afify, PE, LEED-AP, director of engineering at New York-based

Clifford Dias Consulting Engineers, is a member of the ASHRAE group

devoted to the study of VRF. In general, he estimates the initial

cost of a VRF system to be 20 to 40 percent higher than a traditional

split/heat pump HVAC system, but, he says, operating costs might

be at least 10 percent less. According to Afify, the difference in

price between a VRF and a conventional system might be recovered

in fewer than five years.

Beyond the initial cost of VRF systems, disadvantages often cited

revolve around refrigerant lines and ventilation. Afify explains

that if VRF systems are large, as many chilled water systems are,

a significant amount of refrigerant gas, instead of water, ends up

running through the building.

“Of course refrigerant is not dangerous within certain volume

limits, but if the system grows huge, it becomes a concern,” he

says, adding that ASHRAE Standard 15, “Safety Code for Mechanical

Refrigeration,” discusses the topic in detail.

Concerning ventilation, Afify explains that providing outside air

can turn into a hurdle, because VRF units may require a separate

ventilation system, especially in hot and humid climates or when

dealing with high occupancy areas. Major manufacturers do generally

offer outside air processing solutions that can be tied into the

same control systems used for VRF units.

More than any of the above setbacks, however, Afify believes that

what has kept U.S. engineers away from VRF systems has been a lack

of familiarity and clear documentation. As more U.S. engineers become

familiar with the technology, many in the industry expect to see

VRF systems grow in popularity. |