| There's More Than One Way to Skin the Louisiana Superdome

Summary: Construction began this month on the skin replacement of the iconic Louisiana Superdome in New Orleans. Baton Rouge-based Trahan Architects is the lead architect for the restoration and upgrading of the stadium, damaged by Hurricane Katrina in August 2005. Trahan Architects has overseen all phases of the $200 million of repairs and enhancements. Trahan Architects’ sustainable skin design is the final phase of the restoration project. Construction is scheduled to be complete in May 2010.

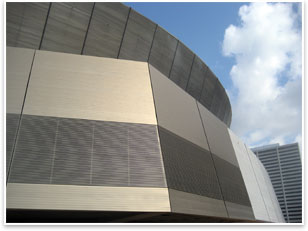

Aluminum skin acts as a rainscreen The new skin will be stronger and made of light-bronze anodized aluminum panels, each 12 inches by 25 feet. The new panels have the same shape as the original skin panels, however they will be affixed without rivets, allowing for individual panel replacement. At the four concourse corners, the panels have windows covered by louvers. This provides both views into and out of renovated club lounges and sun shading to reduce cooling costs.

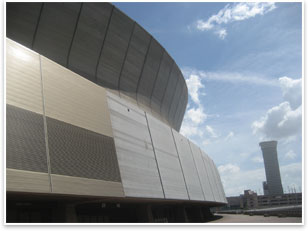

The new covering also opens up the corners on the lower concourse, allowing the Superdome to connect to the urban surroundings. Trahan refers to the original Superdome as an introverted vessel within an urban context. “When the Superdome was built in 1975, there was very little around it,” he says. “Now there are office buildings, restaurants, and retail. To make a contextual connection, we removed the opaque panels and inserted a glazing system on the corners, with 1x2-inch adonized louvers. This also deals with sun issues relating to specific orientations. The new skin still maintains the monolithic appearance of the dome.”

Testing shows that the foam waterproofing behind the new membrane provides an upgrade in the R value of the system, from 2-4 to 16-18. The system was subjected as well to a rigorous wind and rain testing to achieve current building codes and energy. Trahan hopes the Superdome’s new appearance will be well received. “It’s such an iconic building and occupies an important position,” he says. “We are really proud of how it’s turning out.” |

||

Copyright 2009 The American Institute of Architects. All rights reserved. Home Page |

||

news headlines

practice

business

design

recent related

› Miami Marine Stadium Wins Historic Designation

Learn more about Trahan Architects from their Web site.

Photo Captions:

1.Construction began this month on the skin replacement of the iconic Louisiana Superdome in New Orleans. Note the difference between the new anodized aluminum skin and the original skin.

2.The new skin is made of light-bronze anodized aluminum panels. Note the damaged panels from Hurricane Katrina on the upper wall above.

3.Each panel is 12 inches by 25 feet.

4.The first phase of the adonized aluminum skin replacement project is about to be completed, which is the four club level corners with new glazing and louvers.

5.The new panels will be affixed without rivets, so that if a single panel is damaged it can be replaced without affecting the adjacent panels.

How do you . . .

How do you . . .  Trahan Architects was the lead architect and managing partner of the team that restored the Superdome after Hurricane Katrina, allowing the famous venue to reopen in 2006. The first phase of repair included the replacement of the 10-acre roof and the removal of 4,000 tons of debris, 800,000 square feet of drywall, and 600,000 square feet of ceiling tile. The second phase of work included a functional, aesthetic, and code upgrade of luxury suites and concourses. This included ADA accessible design upgrades wherever possible. In this final, two-part phase, Trahan’s design calls for an exterior skin replacement using anodized aluminum. The new skin will replace approximately 400,000 square feet of exterior aluminum panels damaged by Hurricane Katrina.

Trahan Architects was the lead architect and managing partner of the team that restored the Superdome after Hurricane Katrina, allowing the famous venue to reopen in 2006. The first phase of repair included the replacement of the 10-acre roof and the removal of 4,000 tons of debris, 800,000 square feet of drywall, and 600,000 square feet of ceiling tile. The second phase of work included a functional, aesthetic, and code upgrade of luxury suites and concourses. This included ADA accessible design upgrades wherever possible. In this final, two-part phase, Trahan’s design calls for an exterior skin replacement using anodized aluminum. The new skin will replace approximately 400,000 square feet of exterior aluminum panels damaged by Hurricane Katrina. The first part of the $18 million adonized aluminum skin replacement project is about to be completed. The new skin for part one is located at the four concourse corners and features glazing and louvers. The next part of the skin replacement will cover the rest of the exterior of the building and be completed in 12-14 months.

The first part of the $18 million adonized aluminum skin replacement project is about to be completed. The new skin for part one is located at the four concourse corners and features glazing and louvers. The next part of the skin replacement will cover the rest of the exterior of the building and be completed in 12-14 months.

More than skin deep

More than skin deep