Recycled Porcelain Creates Sustainable Terrazzo Finishes by Russell Boniface

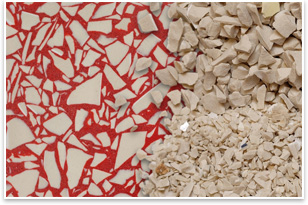

Summary: Architects are taking an interest in Plano, Tex.-based designer Tim Whaley and his firm EnviroGLAS for their terrazzo countertops and hardwood floors, recycled from porcelain toilets, sinks, and tubs. Whaley’s trademark countertops and hardwood floors, named EnviroMODE, also are getting attention in the form of awards from both the National Recycling Coalition and the Texas Commission on Environmental Quality and have been showcased at venues such as last month’s Greenbuild conference in Chicago. Whaley and his company hope to exhibit their recycled terrazzo products at the AIA 2008 National Convention in Boston in May. Whaley and EnviroGLAS acquire both used and unused toilets, sinks, and tubs—all on their way to Dallas landfills—to reuse as terrazzo countertops and hardwood floors. The used porcelain is sanitized, and all reclaimed porcelain is crushed into bits to become their VOC-free terrazzo products, called EnviroMODE.

City of Dallas came calling

Whaley acquired 100 tons of their discarded toilets but had to pay for its transportation. “We had 10 trucks of broken toilets shipped to Marble Falls, Tex. We worked with a firm called Cactus Canyon—they brought the toilets into their facility and crushed them with a rock crusher.” Once Whaley and EnviroGLAS had the porcelain particles, they hand-ground off the enamel surface and mixed in epoxy resin. Whaley worked with a separate company to polish the bits.

Whaley notes there’s no difference in reusing porcelain from used and unused toilets other than the sanitation process of cleaning and drying the used toilets, which he admits is a bit of trial-and-error, without the use of any special chemicals. “The main thing is the vitreous china is protected on its surface with baked enamel to keep the toilets from deteriorating on the inside.” Whaley is looking at outsourcing the sanitizing to a firm that might have an available large tank.

A visit to the AIA convention in Boston could be in the offing. “We think change takes time, effort, and education. I truly see this not as a hoax or spin on a new product, but rather a product that has sustainable clout. It’s wrong to think that because porcelain is broken that it doesn’t have any more performance.”

|

||

Copyright 2007 The American Institute of Architects. All rights reserved. Home Page |

||

home

news headlines

practice

business

design

recent related

› 21 Projects Honored in Inaugural Lifecycle Building Challenge

› AIA Architects Walk the Walk on Sustainable Design

› Design a Better World by Taking the ENERGY STAR Challenge

Visit the AIA Committee on the Environment online.