03/2005

102,350-square-foot facility serving 250 buses is registered with the U.S. Green Building Council

The

City of Tempe (Ariz.) Redevelopment Review Committee recently approved

conceptual designs for the new East Valley Bus Operations and Maintenance

Facility, designed by the team of RNL Design, Phoenix, and Maintenance

Design Group (MDG), Denver. The facility will be certified at the Silver

Level, making it the largest and one of the first bus maintenance facilities

in the U.S. to receive Leadership in Energy and Environmental Design

(LEED™) certification from the U.S. Green Building Council, ensuring

that the project meets specific sustainable, energy-efficient, and water-saving

criteria. (The Silver Level is a step above the Certified Level in USGBC’s

progressive certification levels.)

The

City of Tempe (Ariz.) Redevelopment Review Committee recently approved

conceptual designs for the new East Valley Bus Operations and Maintenance

Facility, designed by the team of RNL Design, Phoenix, and Maintenance

Design Group (MDG), Denver. The facility will be certified at the Silver

Level, making it the largest and one of the first bus maintenance facilities

in the U.S. to receive Leadership in Energy and Environmental Design

(LEED™) certification from the U.S. Green Building Council, ensuring

that the project meets specific sustainable, energy-efficient, and water-saving

criteria. (The Silver Level is a step above the Certified Level in USGBC’s

progressive certification levels.)

The new 250-bus facility, owned and operated by the City of Tempe, will

include 75,600 square feet of maintenance space, 7,100 square feet of

fuel and wash space, and 19,650 square feet of administration and operations

space. The city and the design team are working together to implement

the facility’s sustainable design, while the city also pursues

sustainable design for its Tempe Transportation Center project.

The new 250-bus facility, owned and operated by the City of Tempe, will

include 75,600 square feet of maintenance space, 7,100 square feet of

fuel and wash space, and 19,650 square feet of administration and operations

space. The city and the design team are working together to implement

the facility’s sustainable design, while the city also pursues

sustainable design for its Tempe Transportation Center project.

“The bus operations and maintenance facility offers a terrific opportunity for incorporating green building principles,” says Bonnie Richardson, AIA, architect and principal planner for the City of Tempe’s Transportation Division, and a LEED-accredited professional herself.

The process starts with site design. “We can reduce the local heat-island effect and recharge the groundwater by using permeable paving or stabilized decomposed granite for employee parking,” Richardson says.

Water conservation is key

Water conservation is key

Tempe’s Transportation Division provides transit services to Tempe,

Scottsdale, and the surrounding areas as part of the Regional Public

Transportation Authority/Valley Metro Transit Agency. Water conservation

is a key consideration for this hot, arid area, especially at a facility

where 250 buses will be serviced and washed daily. “We have the

chance to focus on water conservation on this site: filtering, storing,

and reusing gray water while reducing the demand for water from the city’s

system,” Richardson explains. “Energy conservation is another

area of focus, using high-performance systems, natural light, and alternative

sources of energy to reduce operational expenses and optimize energy

performance.”

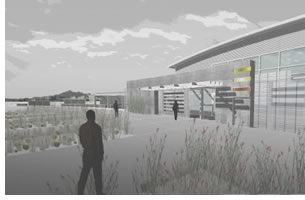

In deference to the site’s proximity to Sky Harbor airport, its

buildings are defined by large, curving roof structures. The 25-acre

complex places its administration/operations building, which is accessible

by the public, at the site’s east end, with a large, curved spine

canopy both defining and shading the public plaza and entry. The architects

placed the maintenance building and other facilities within a secured

yard. The design for both buildings employs sleek metal panels and tilt-up

stained concrete panels in reference to the buses and transportation

functions they house. Daylighted spines and curved-roof volumes throughout

open to the north and are complemented by the extensive use of curved

tensile fabric at the bus canopies and other locations.

In deference to the site’s proximity to Sky Harbor airport, its

buildings are defined by large, curving roof structures. The 25-acre

complex places its administration/operations building, which is accessible

by the public, at the site’s east end, with a large, curved spine

canopy both defining and shading the public plaza and entry. The architects

placed the maintenance building and other facilities within a secured

yard. The design for both buildings employs sleek metal panels and tilt-up

stained concrete panels in reference to the buses and transportation

functions they house. Daylighted spines and curved-roof volumes throughout

open to the north and are complemented by the extensive use of curved

tensile fabric at the bus canopies and other locations.

Richardson has great hope for the future of sustainable design in Tempe. “The RNL and MDG team has done a great job of designing a functional, attractive facility that will help set a new standard for sustainable building in Tempe,” she says. “Their thoughtful and creative approach to the environment and the health and productivity of the employees will benefit the city and the surrounding communities far into the future.”

Design is slated for completion in August 2005, with construction to begin this fall.

Copyright 2005 The American Institute of Architects.

All rights reserved. Home Page ![]()

![]()

|

||

|

|

||