Cold-formed

steel (CFS) is durable, strong, and recyclable, points out the Partnership

for Advancing Technology in Housing (PATH), a public/private program managed

and supported by the U.S. Department of Housing and Urban Development,

in a September 2002 report.

Cold-formed

steel (CFS) is durable, strong, and recyclable, points out the Partnership

for Advancing Technology in Housing (PATH), a public/private program managed

and supported by the U.S. Department of Housing and Urban Development,

in a September 2002 report.

Moreover, CFS-supported floor/ceiling, wall, and roof systems can be designed to be at least as fire and sound resistant as traditional wood-supported components in house construction, the report states.

A 30-minute fire-resistant rating (per manufacturers’ ASTM E119 testing) “is readily achievable using one layer of ½-inch (12.8 mm) gypsum wallboard, and 60 minutes is achieved using multiple layers of gypsum wallboard,” Residential Steel Framing: Fire and Acoustic Details reports. “Board materials such as gypsum boards, cementitious boards, or gypsum fiberboards for walls and ceilings, and timber-based boards for floors can readily provide up to 120 minutes of fire protection.”

CFS has a tendency to lose strength markedly at 740 degrees F (390 degrees C), which is why the report advises fire protection, including mineral wool insulation. “[W]hen multiple layers of boards are used, their joints should be staggered to maximize integrity in fire,” the authors add.

Gypsum makes it quiet,

too

The sound transmission class (STC) of a 1-5/8-inch steel stud wall (24"

o.c.) with ½-inch gypsum board on both sides is 39, which is the

equivalent of a wall with 2x4 wood studs (16" o.c.) and the same

½-inch drywall sheathing. At an STC of 39, normal speech is audible,

and televisions and stereos are clearly audible, the report explains.

Somewhat more acoustic separation (STC 44) is achieved with 3-5/8 inch

steel studs (24" o.c.) with 5/8-inch gypsum board on each side, which

is the equivalent of a cinder-block wall (STC 45).

Because any stud-wall system is lightweight, such

systems require special design considerations to minimize air- and impact-transmitted

sound. Increasing the mass with additional layers of gypsum board and

filling the space between the gypsum-board leaves are typical ways to

increase the STC of a stud wall. The report suggests three more strategies

for CFS-supported walls.

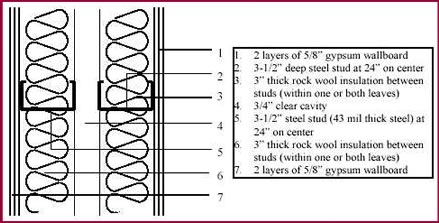

• Two separate parallel stud walls are often constructed with a small

cavity (0.8 to 2 inches or 20-50 mm) between them. They have minimal structural

connection, each with a gypsum board finish to the room side. The walls

act to a large extent as two independent walls, and the acoustic separation

can nearly be doubled.

• CFS studs can be designed to reduce the transfer of sound by introducing

some resilience in the web or by specially shaped studs.

• Resilient connections between the gypsum board lining and the steel

also increase flexibility and reduce sound transmission. The connection

can use cold-formed resilient steel channels (also called bars) or acoustic

profiles that have a corrugated web installed perpendicular to the studs

and to which the gypsum board is attached.

Copyright 2002 The American Institute of Architects. All rights reserved.

![]()

|

Only 1 percent of new housing starts in the U.S. involve CFS systems. If you have experience with these applications and have comments you’d like to share, send us an email. For the full 130-page HUD publication, created via the Partnership for Advancing Technology in Housing (a 3.18 mb PDF file), click here.

|

|